I’ve recently completed a couple rifle builds, and while I was working on them I was on the lookout for a new bipod. I currently run a couple Harris-style bipods that switch between rifles, and one really odd piece of kit that sits on my SKS. I was looking for something different, something better. Top of mind for competition shooting (PRS-style matches) was something like the Harris or Atlas offerings – but then I stumbled on something really unique – Protean Innovations.

I saw some of their bipods in pics and videos on their Instagram page, and I was instantly intrigued. The bipods seemed to be built for exactly the kind of shooting I had in mind. I reached out to see if I could get a unit to test and evaluate, and their CEO Kyle Hayes, got in touch and offered to send me some gear to check out. A week or two later I received a nice little care package with a Gen II bipod and the Stability Tracker bipod (which is their gen 3 model, effectively). Also in the parcel were a bunch of Protean Innovations accessories. And not for nothing, a personal letter signed and sent by Kyle himself. That says something about the kind of company they are.

First impressions

First things first, opening this package was awesome, not only to get some new gear to test out, but also because of the way they package their products. Instead of plastic and cardboard, the Protean Innovations bipods came in their own camo pouches. These can easily be attached to molle webbing, a belt, or whatever else you want. Pro Tip: They also make great water bottle pouches to go on your belt when you’re hunting.

Looking the units over the first thing I noticed was the quality of the materials, workmanship and anodizing/coating. Despite a lot of aluminium-on-aluminium, there is no discernible friction in the system, and all tolerances seem to be exactly right for flawless deployment – precisely what you want in a “quick deploy” kind of system.

Testing

My primary use for these bipods would be for my competition guns, so that’s how I decided to test them. Of course they’re just as applicable to hunting or LE/MIL scenarios, but that’s not my use case, and I’ll leave it to other reviewers to cover those bases.

In terms of competition, I’ve used these at the PSNZ22 run by Precision Shooter, the TSCC Practical Rimfire shoot run by Gillice Practical Rifle Events, and the CNIGC Good Morning Vietnam shoot. I’ve also used the Stability Tracker bipod to get my bolt action centrefire competition rifles ready, but haven’t competed in F-Class this season.

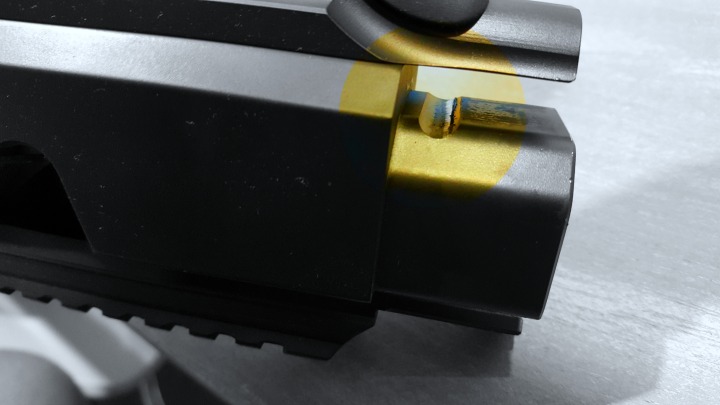

Gen II Bipod

I ran the Gen II bipod on my 22LR HK416D, using the quad rail on the forend to mount the system. The Protean innovations bipod slides along the rail when you hold the deployment trigger, and catches into position when you let go. This allows you to deploy it securely at multiple angles. This can be great for practical shooting competitions, where you often shoot from angled positions, or through barricades/obstacles that have very specific fields of view at certain heights from the ground. For those thinking of a hunting application, it means you can lower your profile as you shoot downhill from a ridge into a valley, or something like that.

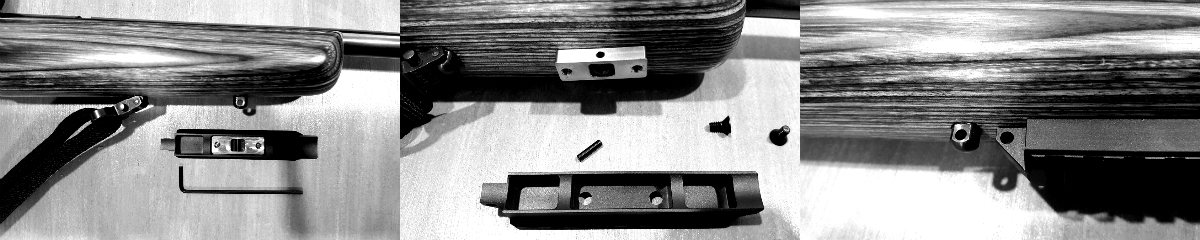

What if you don’t have a rail on the bottom of your rifle? Protean Innovations sells a simple and cost-effective adapter, called the Stability Rail, that will attach to your sling swivel stud and give you an easy to use picatinny rail. There are, obviously, other conversion system out there, if you prefer something else.

In this competition, which has a lot of positional shooting and some stages which cannot be shot supported, I used the Stability Grip attachment. This acts as a forward pistol grip, and attaches to the bipod deployment trigger. You can still pull the trigger and move the pistol grip forwards or backwards to deploy or retract the bipod.

I found this system great. It not only allowed me to quickly transition between off-hand and prone-supported positions, but the pistol grip allowed me to take more controlled standing shots, and be confident in my ability to quickly deploy the bipod, without having to play with small buttons or release levers.

Oh, worth a mention, you only need to pull the deploy trigger and slide it forward or backwards to manipulate the bipod. Unlike a Harris bipod, you don’t need to reach all the forward of your rifle and pull back the individual legs. You can stay completely in position on the rifle.

Other accessories that really make this a unique system include the Stability Spiked Shoe and the standard Stability Feet. The feet that come on the bipod from the factory are a quite grippy rubber design, and have a bit of bend in them, allowing you to achieve those angled positions in the field. With the extra grip you get compared to bipods with hard or round feet, you don’t get nearly as much “hop” or “bounce” when shooting larger centrefire rifles on hard surfaces, such as concrete benches or floors.

The spiked shoes are easily slipped over the rubber feet in seconds, and stay completely secure. This is a revolutionary approach to bipod feet. While there are endless options for more traditional bipod systems, they usually require tools and can take minutes to switch over – not ideal for field use or in high-pressure competitions.

I thoroughly enjoyed using this bipod in competition, and although I didn’t have my best day shooting, I can confidently say the Gen II and Stability Grip combination greatly enhanced my ability to tackle a very creative shooting course put on by Kerry, Matt and the others from the Precision Shooter crew.

In fact, I ran this bipod again at the Good Morning Vietnam shoot, put on by Central North Island Gun Club, and I can honestly say that without it, I would not have achieved my 3rd place in Open Division.

I was shooting my Aero Precision build, with most parts from NZAR15.com, and yes, I was that guy with the muzzle brake on the competition line. I heard all the comments behind me. However, I wasn’t the only one! So was the guy on my left, and the guy on my right! Thankfully only .223, with .308 and 7.62×39 further down the line.

But, even still, it was quite difficult to maintain a good sight picture with vented muzzle gas coming directly from another competitor’s rifle and getting in behind my glasses, making my eyes sting and glasses fog up in any longer strings of fire.

So, in the couple courses of fire where a supported prone position was allowed, the extra stability, and the option to quickly deploy after running to the firing line, all helped me get rounds down range before my vision became too impaired, and helped me to stay on target when my eyes were dripping tears from the stinging gas exiting the filthy brake next door.

Stability Tracker

Now this is the next evolution in bipods and shooting support. Yup, this is the version after the Gen II, and the features show.

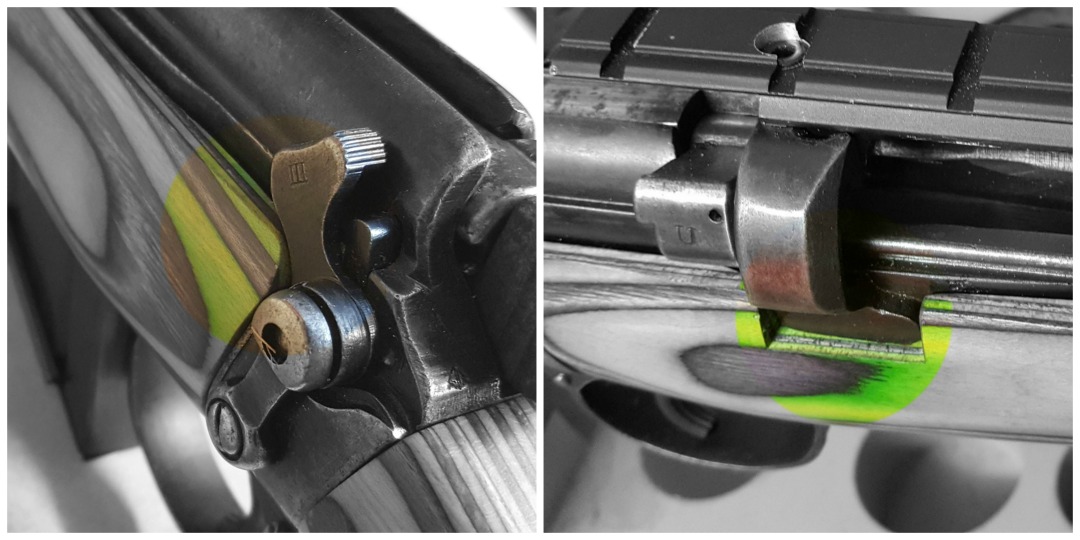

The appearance is refined, and weight reduced, with a single locking mechanism (compared to the two on the Gen II). The function is smoother, and the front attachment trigger is smaller, and less obtrusive.

Another feature which aids smooth operation is the integral picatinny rail which the bipod operates on. With rounded and lower profile rail slots, the operation is greatly eased. The whole unit still attaches to your picatinny rail, but less real estate is taken up for the operation of the system, as the guts of the bipod hangs below and moves on its own mechanism. This also allows Protean Innovations to introduce the piece de resistance, the tracking feature.

With a simple flip of the tracking trigger with either your left or right hand, you can now pan your rifle on the horizontal axis, without moving position or lifting your bipod from its place.

For moving targets this allows you to easily introduce lag or lead without twisting the rifle or running out of horizontal movement, which is very limited on traditional bipods. In competition with multiple targets at varying distances and placements from your shooting position, this can mean being able to engage more targets from the same firing position, without having to move and add time to your run.

To lock the bipod back in place, all you have to do is flip the trigger back to its original position, and as the rifle tracks around to centre, it will click in place. It couldn’t be easier.

I used the Stability Tracker bipod, as well as the Stability Grip again, for Simon Gillice’s practical 22LR event. The bipod ran flawlessly, and as at previous competitions, I had a few people coming up to me and asking where and how they could get their hands on what is objectively a cool looking setup.

I did have one failure one the day, and as always, I tell the bad with the good. Between stages I noticed the pin on the tracking trigger was coming loose. Thankfully it didn’t pop out during the stage, or it would have been gone forever. So, I pushed it back in and stopped using the tracking feature for the day, and it was otherwise absolutely fine.

When I got back home, Kyle proved again, exactly the type of company they are. He gave me instruction on how I could stake the hole with a nail and hammer, similar to how you stake an AR15 bolt carrier. This repair worked and has lasted well. But, he didn’t stop there. Kyle later informed me that they took the feedback on board, and had sourced oversized pins to stop this happening in the future. This is a company that is dedicated to a quality product and, as their name says, innovation.

This excerpt below from an email directly from Kyle shows that not only did they seriously consider the issue around the pins, but also that they are constantly refining the design, and looking for better ways to support your rifle.

“For a long term solution I have located a supplier here in the US that makes pins that are oversized. This will eliminate this issue all together. We are continually refining the design. The next production run will have a few enhancements where we will remove some more weight without compromising strength, we will fix the press fit pin issue, and we are working on trimming up the leg extension triggers as well to remove more weight. All in all it should all be even better on the next go around by the time we get to it.”

I did also ask Kyle if a canting version would ever be on the market, but he (quite reasonably) said the R&D showed it would not work. He did do the entire redesign, but found that it added considerable weight, unnecessary complexity, and extra moving parts which made the bipod noisy. With all that weighing against the cant feature, he decided not to pursue it. Not to mention the increased cost to the consumer of the extra feature, which would push the bipod into a price bracket that is probably not viable for your average Joe.

I was glad to hear the option had been thoroughly explored before deciding against it, and Kyle has a good point in that you can easily adjust your height using the legs (and extended legs option if you need them), if you often shoot from uneven surfaces. The aim of the system is quick deployment, not lots of finicky adjustment. And if you are on the F-Class line, chances are you are shooting from a flat and stable position. Feedback from PRS shooters and long range shooters has been that a lack of cant has not affected the usability of the bipod.

In our emails, Kyle did say that if he can ever figure out a reasonable way to introduce a cant feature, avoiding the above pitfalls, he will certainly consider it. So, it’s not out of the picture, but it is not a feature the Stability Tracker has right now.

Pros and Cons for the Gen II

The Gen II is a great model, and you can see in it how Protean Innovations continues to evolve their designs. Here are some of the pros and cons of this model.

Pros

- High quality, solid metal construction and finish

- Can be made more versatile with optional extras (spike feet, leg extensions, stability grip)

- Angled shooting positions are easily achieved

- Can lower your shooting profile when shooting downhill

- Bipod feet designs reduces bipod hop from recoil

- Bipod feet design allow for good vertical travel without losing grip

- Quick deployment of a stable shooting platform when needed, quickly stowed when not

- Interfaces with a common MIL-STD 1913 Picatinny rail

- Easily transferable between multiple rifles in seconds

- Easy/quick to extend legs to correct length

- Cheaper price than Stability Tracker model

Cons

- Will need an adapter for chassis or stocks without a rail

- It is possible to overextend the bipod rearward if you are in a hurry (I was!). There is a simple fix. Either, get used to the operation and take your time, or, I mounted a picatinny-sling swivel stud adapter that I had lying around (took the stud out), just behind the rearward most point of travel, stopping it from going too far back. Easy fix. You could achieve the same with a rail riser, cut down scope ring, or any other picatinny accessory

- If you push upwards on the stability grip while pushing the deployment trigger forwards to collapse the bipod, it can be a bit difficult to stow the bipod. This is a user issue – once you get used to it, it works beautifully

- The model is likely to be discontinued as the Stability Tracker takes over as the primary model. If you want one, you’d need to get it in the very near future

Pros and Cons for the Stability Tracker

The Stability Tracker really is next level when it comes to bipods. Here are the pros and cons.

Pros

- All the same pros as the Gen II, except that it is obviously a bit more expensive. Also;

- Ability to pan for lead/lag

- Smoother operation during deployment/stowing, thanks to its own integral rail

- Simplified attachment compared to Gen II is even easier and quicker to use

- Does not have the possibility of overextending during deployment

Cons

- Will need an adapter if you don’t have a rail on your rifle

- For a high-end bipod, lack of cant may put some off, but trade-off for weight/complexity is justified

Is this the right bipod for me?

Probably. I can’t personally think of a time when I would not use this system. I still have and use other bipods, but all of my rifles with rails or adapters will now be sharing Protean Innovation products. They’re so easy to switch between rifles, and I like the idea of using one system across multiple rifles. Building familiarity only increases efficiency.

I would definitely recommend the Stability Tracker for anyone looking to shoot PRS-style matches at a competitive level. For hunting, I love the low-profile capabilities the Protean Innovation bipods give you when shooting downhill. And for range use, it has pretty much eliminated the hop I used to get from my more powerful centrefire rifles when shooting off the bench – this is probably the biggest highlight for me.

If you’re in the LE/MIL line of work, this testimonial from one of their customers might resonate with you:

“We have had one army sniper use the Tracker while deployed in Afghanistan. His testimonial was that he pitched his Harris after one mission and never went back to it afterwards. Said he used the tracker the entire time during his tour and refused to use anything else.”

Summary

If you’re looking for a bipod that is innovative and actually improves your shooting experience, I would not look past the Stability Tracker by Protean Innovations. It is robust, quick to deploy, technologically advanced, and a joy to use. The fact that the company are so good to their customers, take on feedback, and actually continue to innovate, is just a huge bonus.

![The TAC21 by Modular Driven Technologies (MDT). Note the dimensions are for a Remington 700 SA. [Image credit: MDT]](http://www.gunrack.co.nz/wp-content/uploads/2017/02/TAC21-R700-SA_DIMENSION.jpg)