Anyone who follows The Gun Rack on Instagram or Facebook has seen sneak peeks of a very green 303 over the past few months. I’ve really taken my time on this particular gun build, and subsequently the review of this stock, but here it is – The Gun Rack official product review of Boyds Gunstocks’ stock upgrade for the British Lee-Enfield series of rifles.

The build…

This particular rifle is a quiet bush monster. Monstrous in appearance, but suppressed and subsonic in its implementation. There’s a lot that’s gone into this particular rifle, so – fittingly – we’ll do an entire article covering the various bits and pieces, and the decisions that led to each of them.

One decision that was, unfortunately, made for us, is that I’m no longer going to have the rifle Cerakoted, as a dear and valued member of the NZ shooting community, Victor Alberts, passed away recently while on holiday overseas. Victor was the applicator and artist behind Cerakote NZ, so necessarily we’ll be looking to sort out some other means of protecting the metal on this bush gun.

The rifle that defended the free world – twice

The Short Magazine Lee-Enfield (SMLE) rifle was featured in both world wars and a host of conflicts all around the world. Its younger brother is only now being phased out of service with the Canadian Rangers, who will have a locally made, licensed version of a Sako product (T3 CTR). Other weapons have been trialled, but none compared to the reliability of the Rifle No 4 Mk 2 (since 1941 – not bad).

Even still, the old Lee-Enfield is a devastating tool in the hands of irregular forces around the world, who do not have access to more modern weaponry, or who perhaps have an abundance of old Commonwealth stock. With ballistics and firepower not too far off the .308 Win, it’s not hard to see why the rifle has kept pace.

Anyway, I digress. So, this stunning piece of history came to my possession in a sorry state. Which is okay, as I was keeping an eye out for an old beater that could be beautified without destroying a battlefield artifact.

One of the problems with using a wartime rifle (1943), that was mass-produced with unique ‘improvements’ and variations across the world, is that you are bound to run into quality issues. In contrast, I do have a 1942 Lithgow rifle which is beautifully symmetrical and well-machined (even if it is left a bit rough in some areas). But this made-in-Britain wartime specimen is a product of its environment, and loose tolerances, rough surfaces, and poor bluing are to be expected.

In hindsight, I really wish I’d done this build off a Rifle No. 4 instead of an SMLE No.1 Mk iii, as the action lends itself to being rebarrelled to higher-power cartridges, but that may have taken this build in another direction altogether.

If you’re considering a build on a No. 4 or even No. 5 action, Boyds thankfully caters to those, too.

Taking apart the two-piece stock

The Lee-Enfield is everything a modern precision rifle is not. It’s not free floated, the stock is not a single piece and and the ergonomics are all wrong. However it was well-suited to winter clothing and putting a lot of lead downrange, so we can’t really judge the designers for that.

The two piece stock is easily taken apart with some screwdrivers, and potentially a socket driver if you don’t have a really long flat head screwdriver. Check out the easy tutorial here (with lots of pictures!).

Fitting the Boyds Field Stock Design

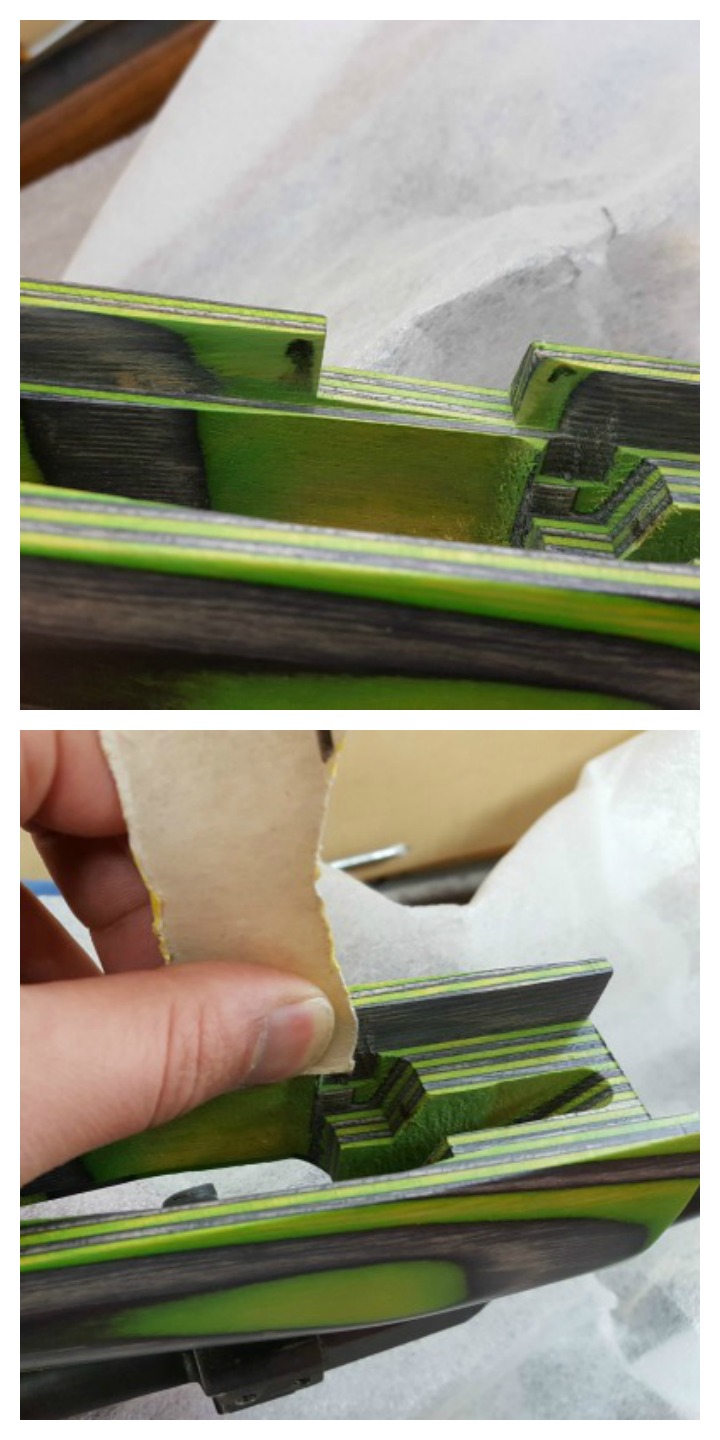

One thing I love about Boyds stocks is seeing the precision lines in the inletting. Now. Take a look at your naked Lee-Enfield. There is not a single square section on that thing. Because the action has so much inconsistency in shape and finish, I spent a fair bit of time sanding and filing around the top of the action and inside and around the sear and trigger slot.

The area around the mag well also needed some relieving of material to get the floor plate sitting properly again, which allowed the barrel channel to move into the appropriate position.

I found it really useful to mark the action with engineer’s blue (a permanent marker will do), to find the high spots on your action that necessitate removing some more wood.

Please be careful removing material, as it’s a lot easier to take off than it is to put on! While I say I spent a lot of time on this, that doesn’t mean I shaved off a lot of the laminate. Rather, I spent a lot of time making sure I didn’t take off too much, so I could still have a snug fit.

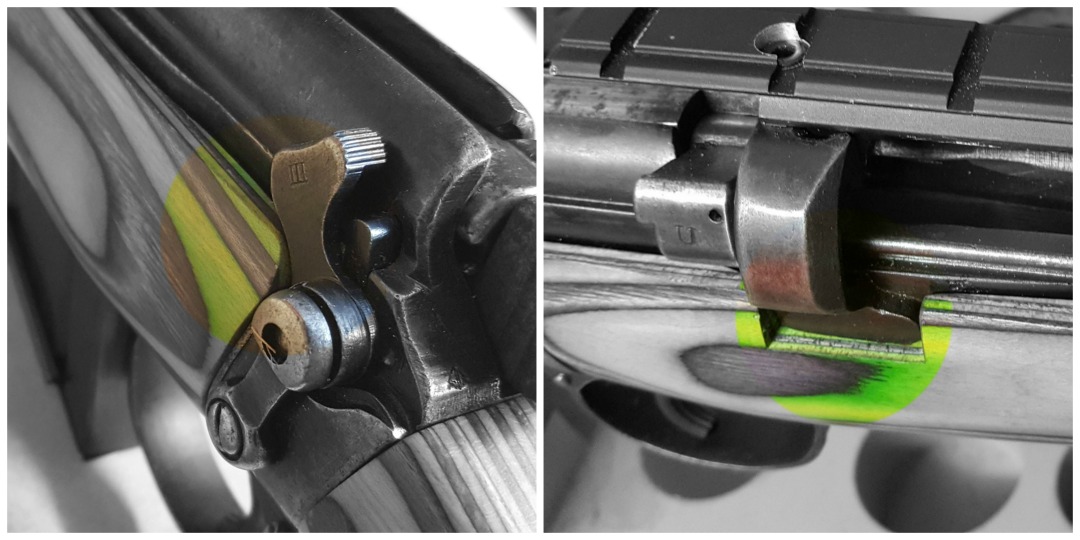

When fitting the butt stock, shaving off a small bit of wood off the top of the donut-shaped insert allowed the laminate stock to snug up nicely when I tightened the bolt. However, on the forend side I found there was a bit of a gap between the wood and the characteristic steel band which forms the rear of the receiver and separates the forend and butt stock. I had a shooting buddy of mine machine up a shim to bridge the gap. He put in some counter sunk holes so that I could screw it into the stock once I had all of the metalwork (including the shim) coated, however it’s so far been held in place by friction and is doing just fine.

The gap between the forend and steel band I’ll put down to variance between manufacturers of rifles over time. I measured this strip of metal on my two SMLE rifles (one year apart, but one from Australia and one from the UK), and found a 1 mm – 2 mm difference in broadness.

You will definitely need to take out some wood where the rear ring of the receiver interrupts the line of the stock, and also where the safety lever goes in the forward position.

Positives of the Boyds Field Stock Design

If you’re looking to improve your Lee-Enfield Rifle or SMLE, you have three options:

- Restore the wood with new old stock or modern replicas (on a No 4 this is feasible, on a No 3, near impossible)

- Put it in a plastic stock, which will reduce weight, but will deliver more recoil, and increase your noise in the bush with its hollow construction

- Choose a hardwood/laminate solution

I’m assuming you landed on option 3, which is why you’re here. The hardwood solution is not only inline with the character of the gun, but also just feels right. I have a couple battle rifles in modern plastic stocks, and I’m too embarrassed to take them to the range, and too put off by the handling and feel to really enjoy them.

The Boyds Field Stock Design (and any of their stocks, really) is a re-imagining of the stock design based around the action and the shooter, not simply a replacement of the existing furniture. This means you can expect an increase in accuracy, stemming from various feature improvements, such as a better inletting, length of pull, cheek weld, positive grip characteristics and also added rigidity when compared to plastic aftermarket (or even original manufacture) stocks.

Line of sight

I found that the Boyds stock in particular raised the eye-line perfectly for the old rifle. With the original stock, if you try and get a positive cheek weld, you’ll be looking at the top of the action. You have to raise your head a bit and compromise your repeatable position on the rifle in order to see the iron sights.

With the Boyds stock, the decreased drop on the comb means you are looking straight at the iron sights. If you had a low mounted scope, you could use this quite easily with little compromise in cheek weld. I have a Vortex Razor HD red dot sight mounted on mine, which, unfortunately, means added height to the optic. However, this doesn’t bother me because, with its unlimited eye relief, I can have my head just about anywhere on the stock and still have an accurate sight picture.

Solid construction

The Boyds stock is not only solidly made with highly advanced resins, but it feels more substantial when you’re shouldering or handling the rifle. The forend fits an adult male hand well, unlike many skinny stocks, where your fingers will wrap around onto the barrel if you’re not careful. It’s also beefier at the butt end. This is in contrast to the original skinny grip that would have been perfect for gloved hands in the trenches, but not user friendly for acquiring a positive grip in the hot bush and forest we often hunt in.

The slight increases in length, width and girth, add up to a much better length of pull and trigger/bolt manipulation characteristics, without increasing the overall length by much at all.

Choice

If you’re pulling apart an old rifle like this to do something special, why not make it truly one-of-a-kind? From the standard colours offered by Boyds, the Pepper laminate is a sexy rendition. Black and charcoal – it modernises any firearm, while still retaining the warmth of wood. There is also a straight walnut stock if that’s your preference.

I chose a Zombie Hunter custom colour for an extra US$16.50, and my rifle stands out like no other. It’s an attention grabber at the range, and it just looks freaking cool. It’s one of those guns you want to take out and shoot, regardless of whether you’re actually working on a load or hunting or just plinking. I might burn through a lot more ammo just because she looks ‘cool’, but that’s okay. Not to mention, everyone else wants a go at it, too!

I also asked for some chequering on the stock, specifically the ‘Scale’ pattern. It’s laser engraved, and absolutely perfect. It adds some extra grip (of course), but also adds depth to the appearance of the rifle. There are a couple other options to choose from as well.

While you’re at it, you could also look at a custom finish, or a different butt pad option to tame your heavy-hitting wildcat magnums.

Negatives

Hey, nothing’s perfect, and there always have to be some negatives.

My only regret on this build (regarding the stock) is not having sling swivel studs, as a sling will be essential for crashing through some of our heavy NZ bush. However, I’m sure Boyds would have included some had I actually thought to ask. Not to worry, I do have some spare, but that’s definitely something I’ll think about next time. More a mistake on my part than a negative with the stock.

There is one negative, and again, it’s not actually a fault of the Boyds Field Design Stock: It’s the rifle. There is no way on God’s green earth that you will have a perfect fit. Unless you own the Boyds’ house action that they model their stocks off.

There is so much variation in fit, quality and manufacturing tolerances between these old war time rifles, that I can almost guarantee some work for you with sandpaper and a file or two, no matter what brand of gun stock you choose. However, if you’re restoring or upgrading any milsurp rifle, this should be something you expect along the way, so don’t let this put you off.

If hard work is not your cup of tea, there are plenty of modern actions that are very uniform and require little-to-no work to customise. Thankfully, Boyds makes stocks for those rifles, too!

Conclusion

At the end of the day, I’ve found (once again) that the Boyds product is a substantial improvement on the original stock that came on the gun. Not only this, but dollar for dollar, I can’t imagine another aftermarket stock coming close.

The customisation options offered by Boyds are a real bonus for anyone looking to increase the appeal of their old shooter, and the standard options are plenty for those who don’t like drawing too much attention to themselves or those who are watching their budget.

Would I buy it again? Yes. And I guess that’s the highest recommendation someone can give after thoroughly testing a product.